Brief: Design a houseware product based in sustainability. (Prof. Will Nickley)

Location: The Ohio State University

Constraints: $100 budget, sustainability, connects to assigned research insights

Collaboration: Partner project with Jason Dionisio (3rd Year Industrial Design)

Description:

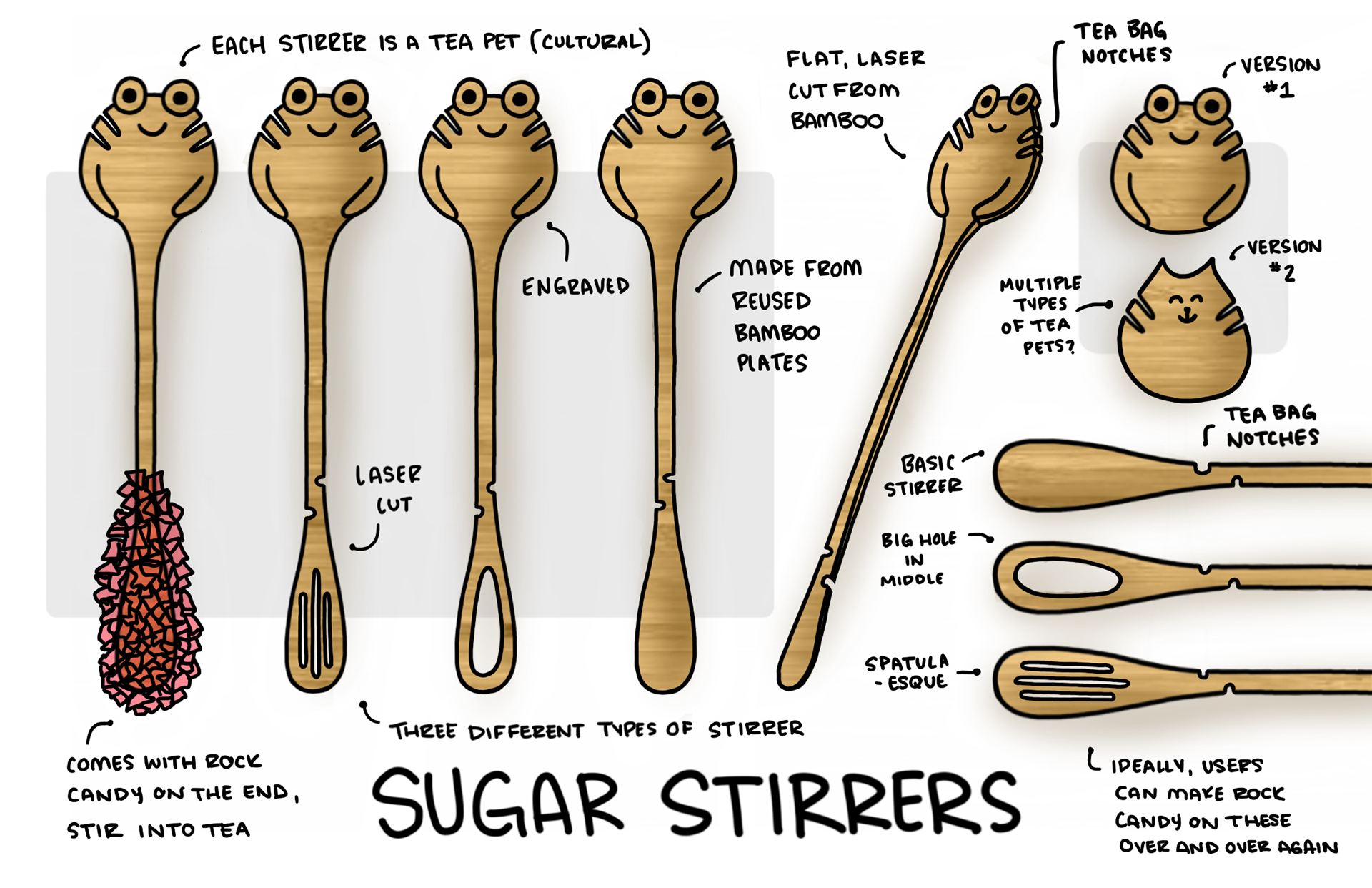

Meet Lollihops: your tea, coffee, and hot chocolate drinking companions. Laser-cut from reclaimed bamboo cutting boards, these drink stirrers are adorned with either a honey or milk chocolate lollipop to melt in your mug, ideal for cold days and cozy nights. For tea drinkers, notches on both ends of the stirrer allow you to tie-off your tea bag. Lollihops are inspired by "tea pets" that originated in the Yuan dynasty of China in the 13th century. These adorable stirrers ensure you’ll always have a beverage buddy. Lollihops are reusable AND top rack dishwasher safe! Lollihops are the perfect stocking stuffer for any tea, coffee, or hot chocolate enthusiast in your life!

Introduction:

The Winter Market industrial design studio is structured in three sections: Research, Development, and Delivery. Students spend a month researching a topic of their choice, then trade insights with another team. With this new research, students develop two housewares products to present to a panel of professionals, who determine which product will be produced for delivery.

The final products are then sold to customers at the Department of Design's Winter Market, with profits benefiting several student organizations.

Research:

Jason and I conducted our ethnographic-style design research at Ohio State's Recreation and Physical Activities Center, the RPAC, studying personal space at the gym. To see our research presentation, check it out by clicking here.

We traded research with classmates Maria Bowman and Easton Nguyen, who delivered several insights on tea and the tea-making process. See their presentation below.

Development:

Maria and Easton gave us three insights:

1. For many, waiting brings an additional value to the tea process.

2. Commercial tea is seen more as an accessory than personal tea.

3. Tea has cultural ties all over the world, but we often do not see them displayed in accessible tea products.

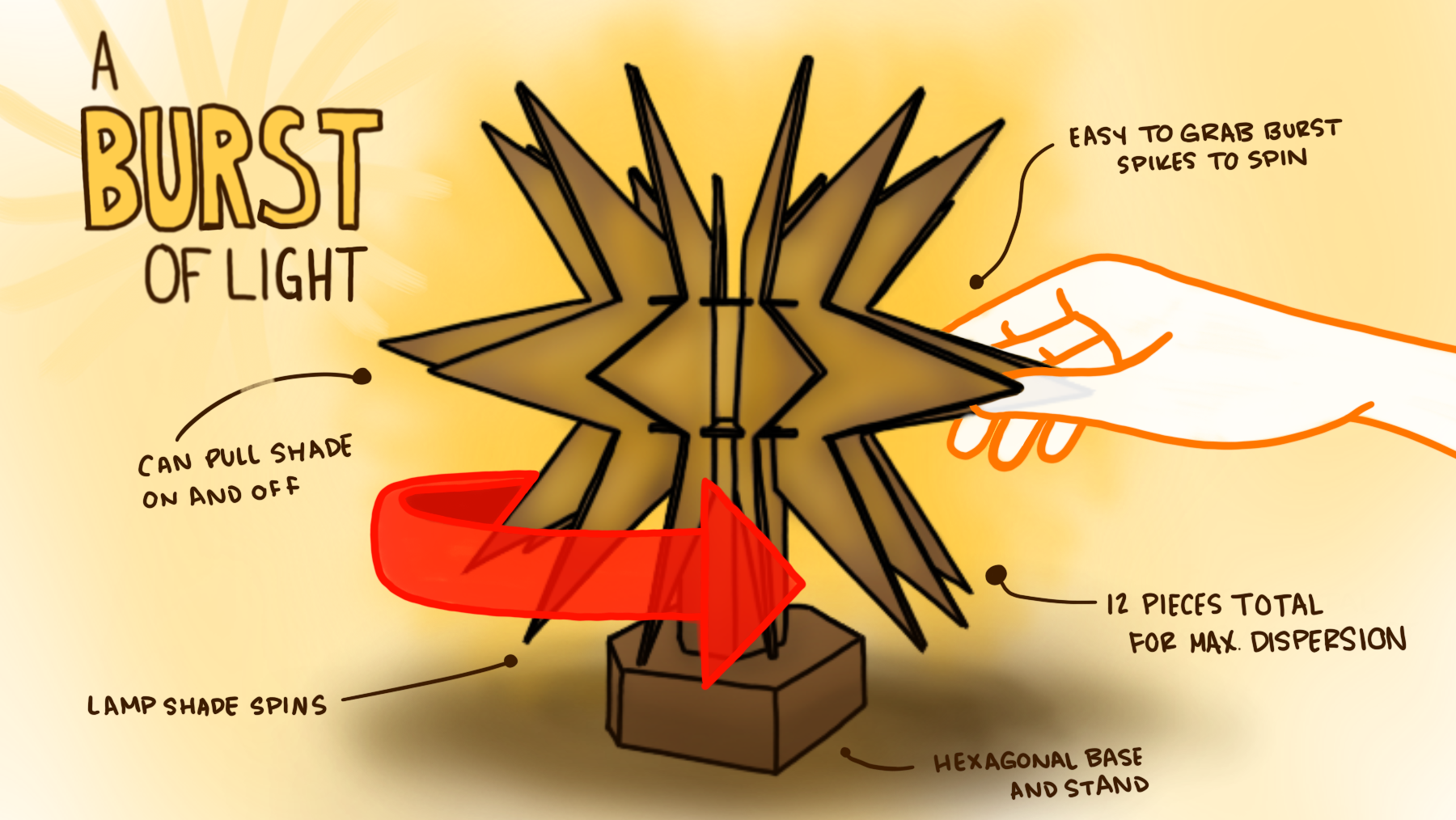

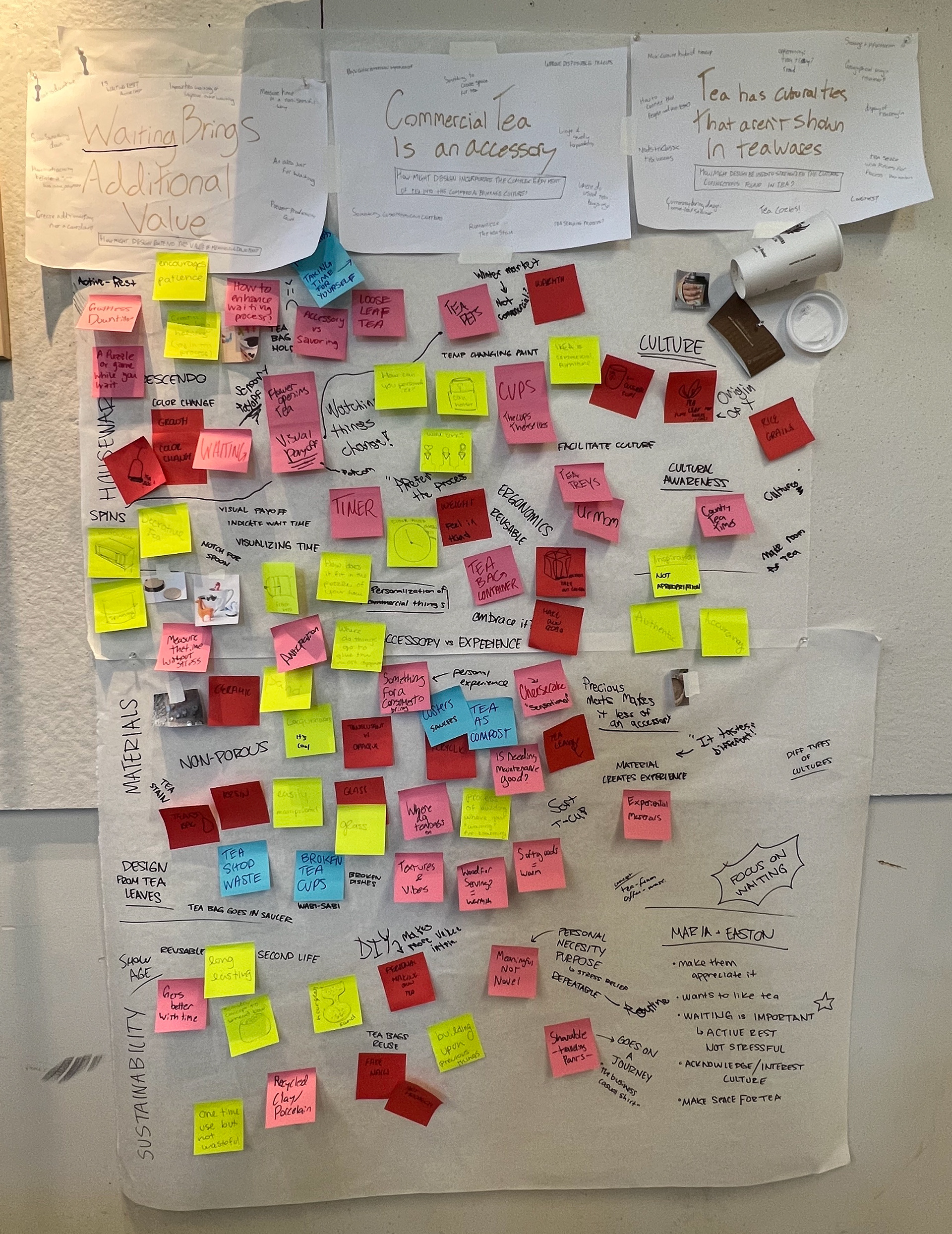

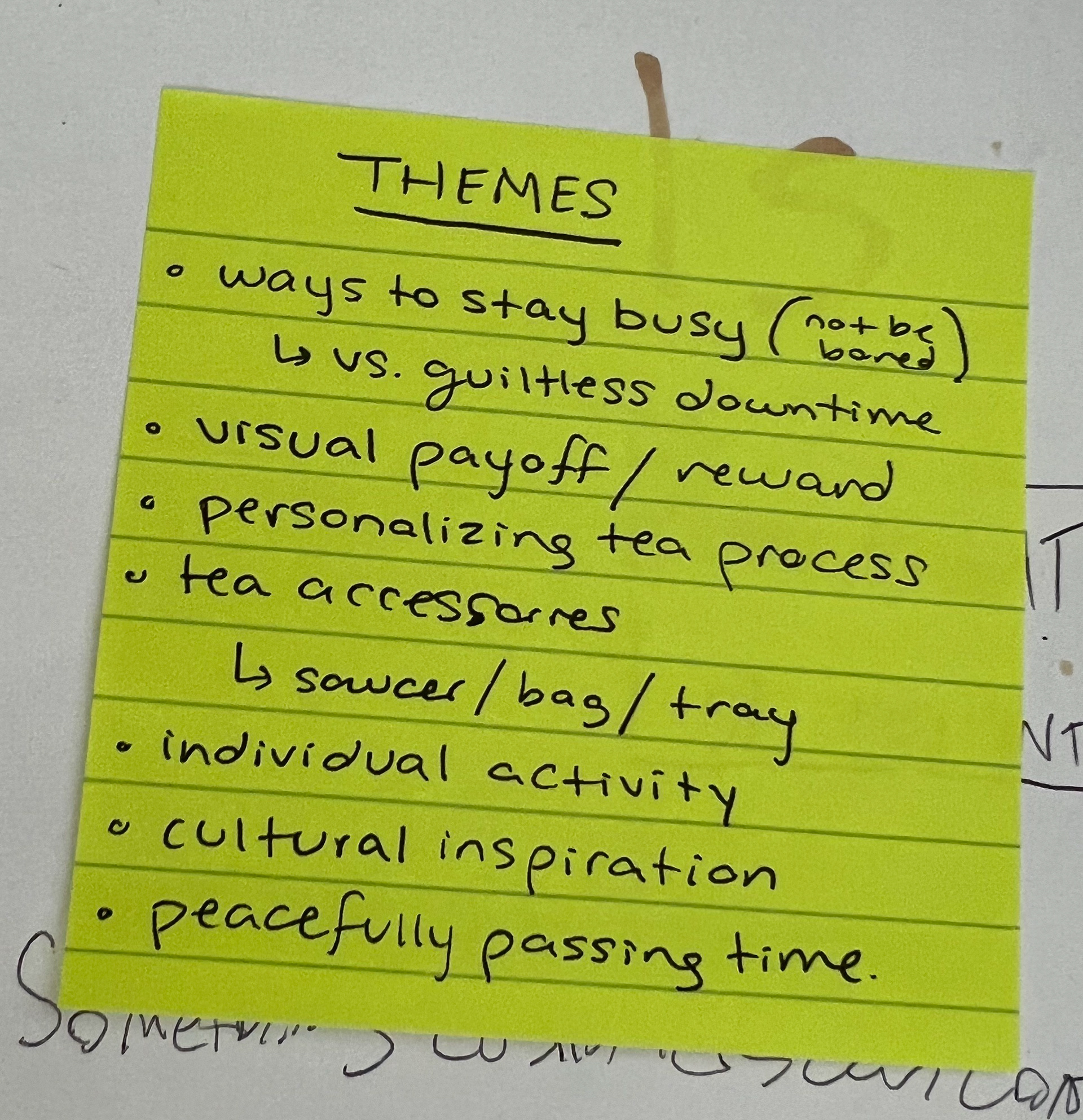

Based on these insights, we spent the next month developing 2 viable product concepts. We started with several brainstorms, identifying major themes for further development.

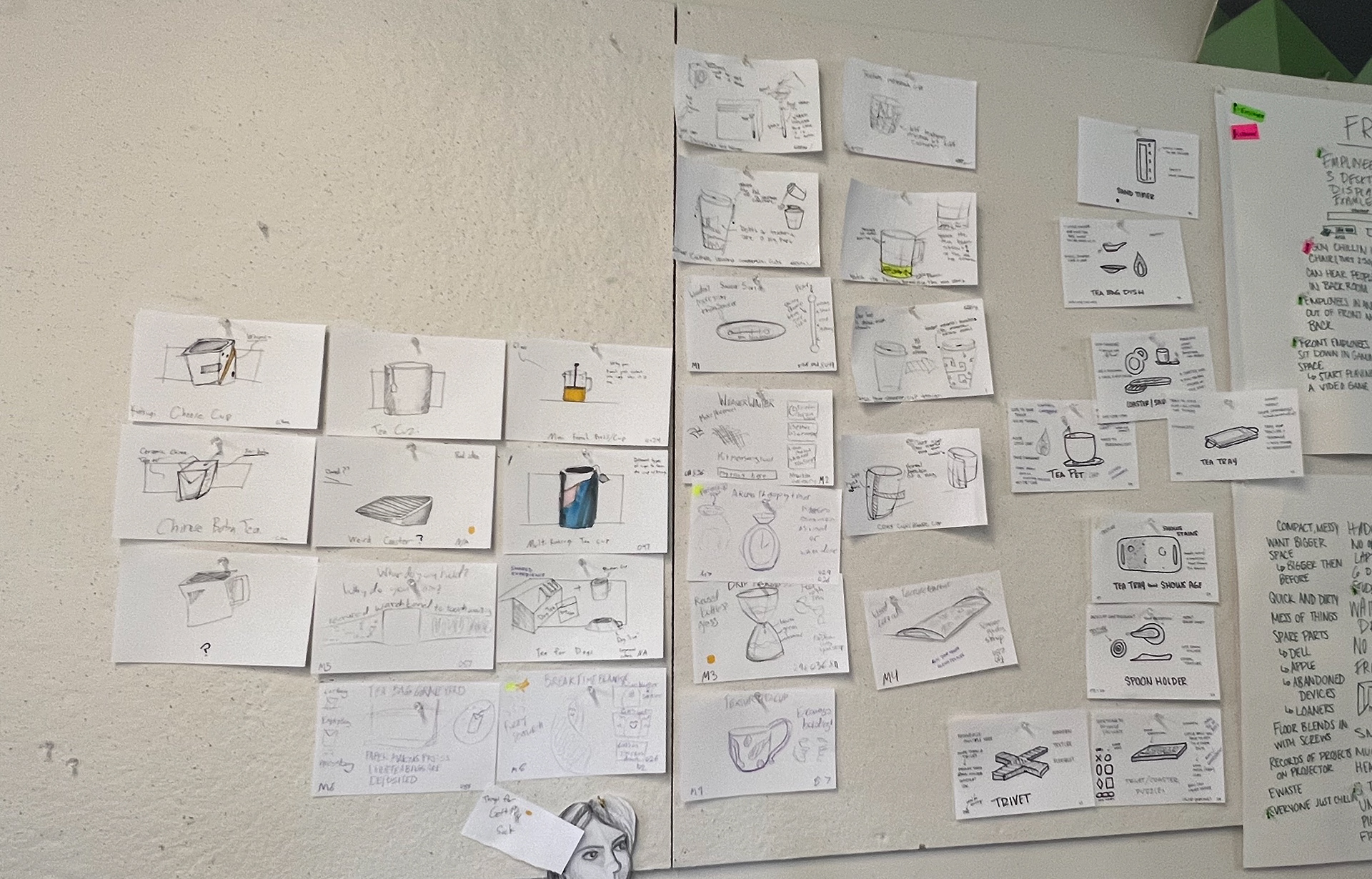

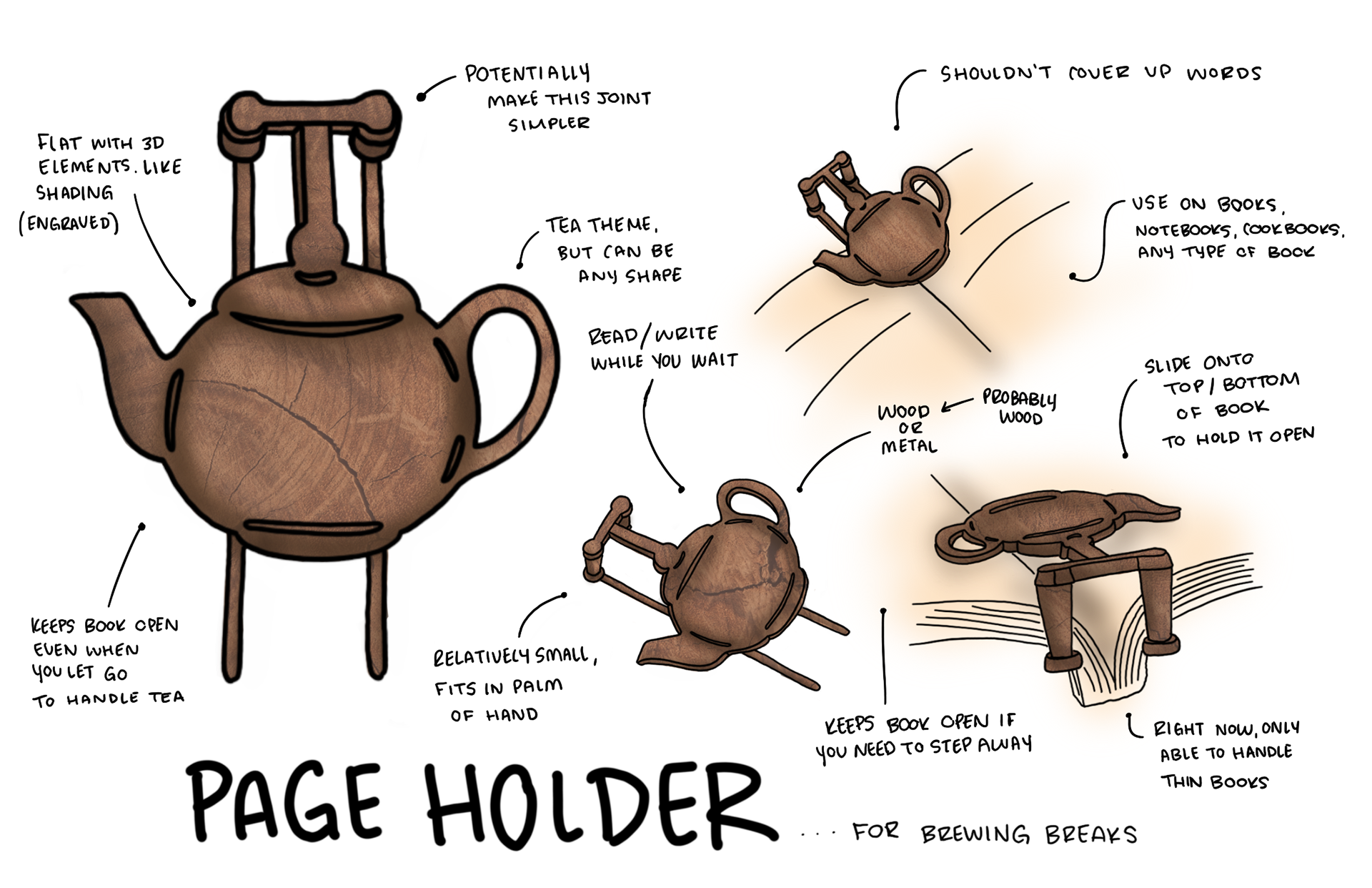

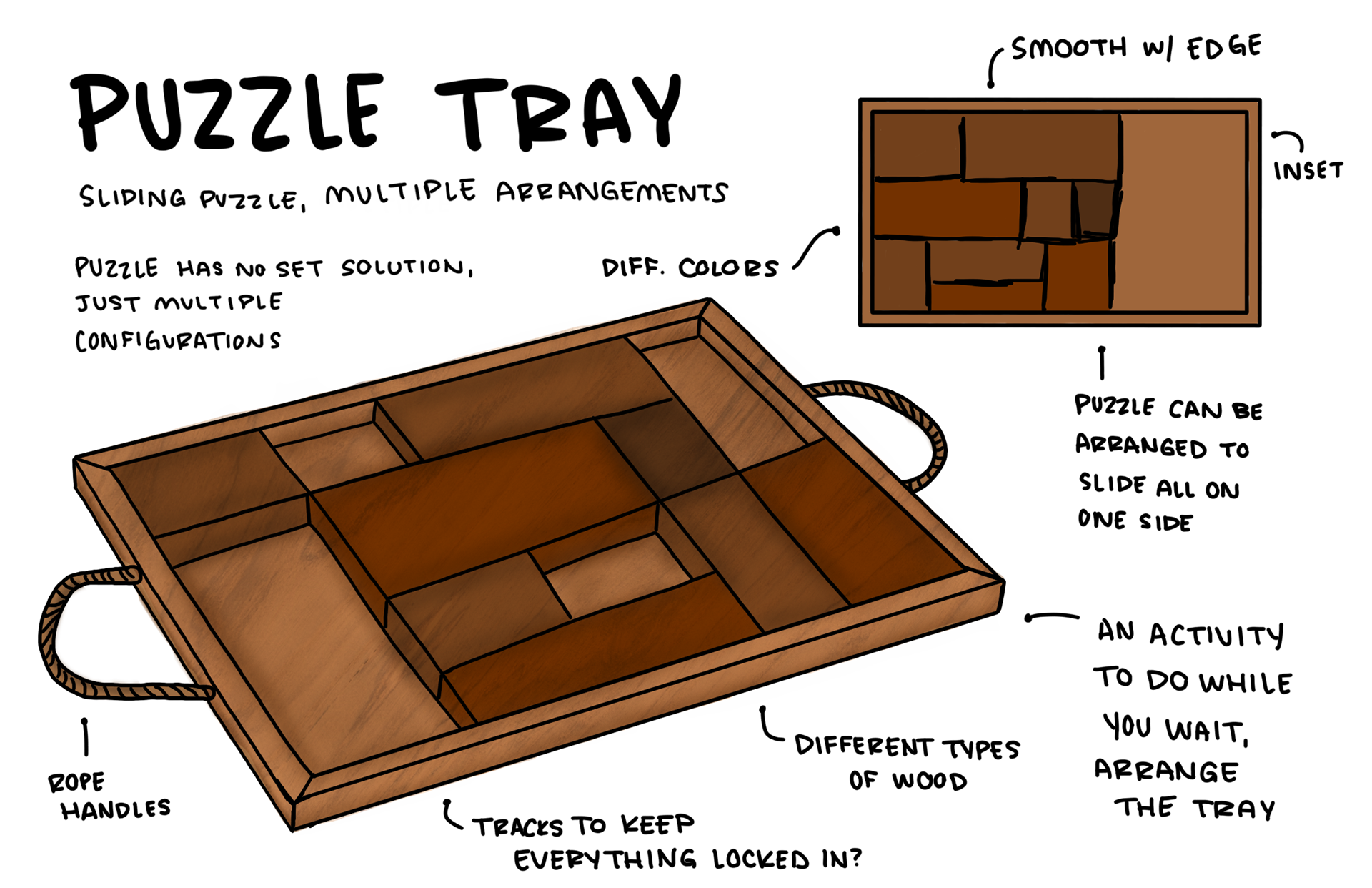

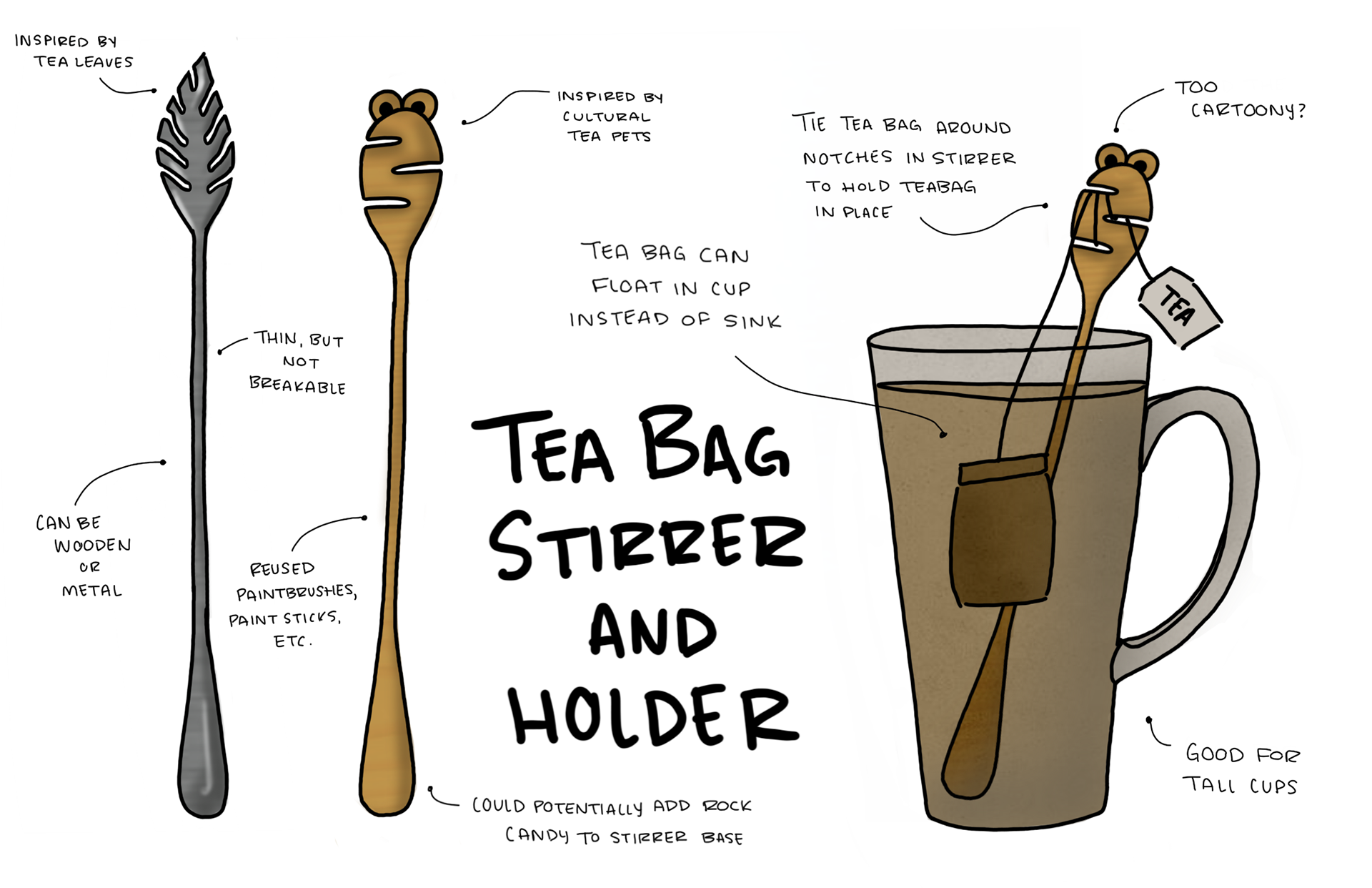

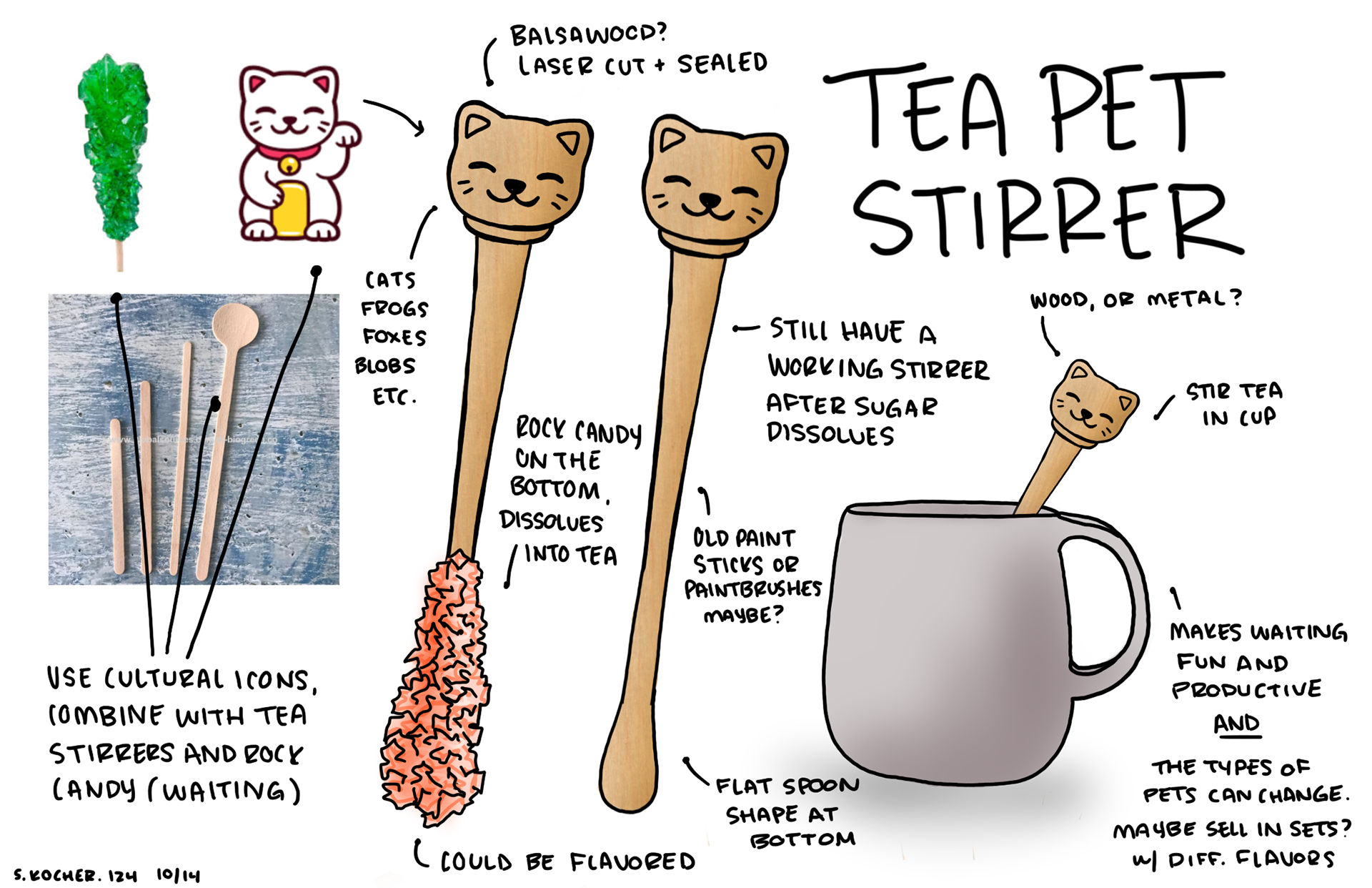

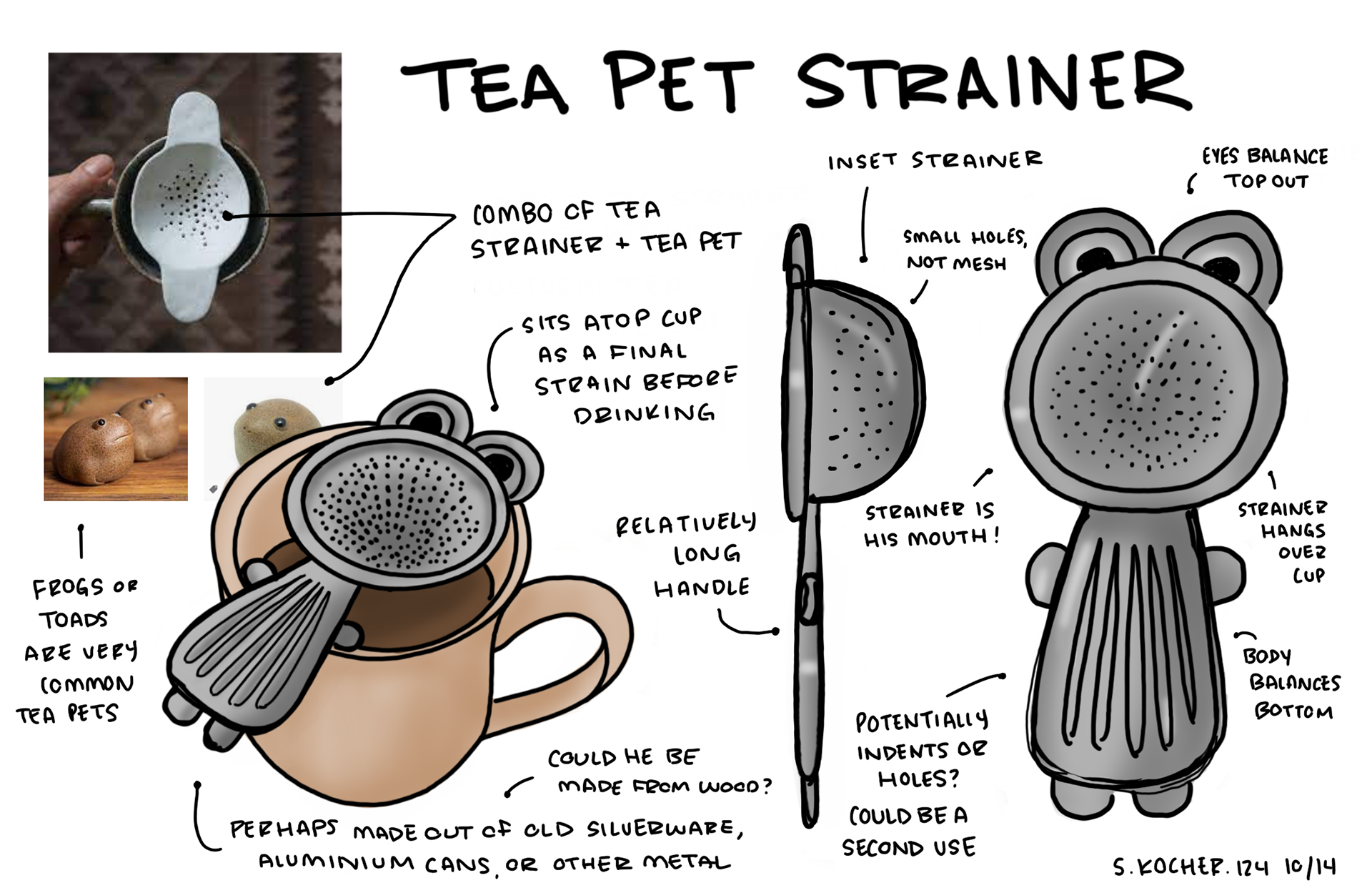

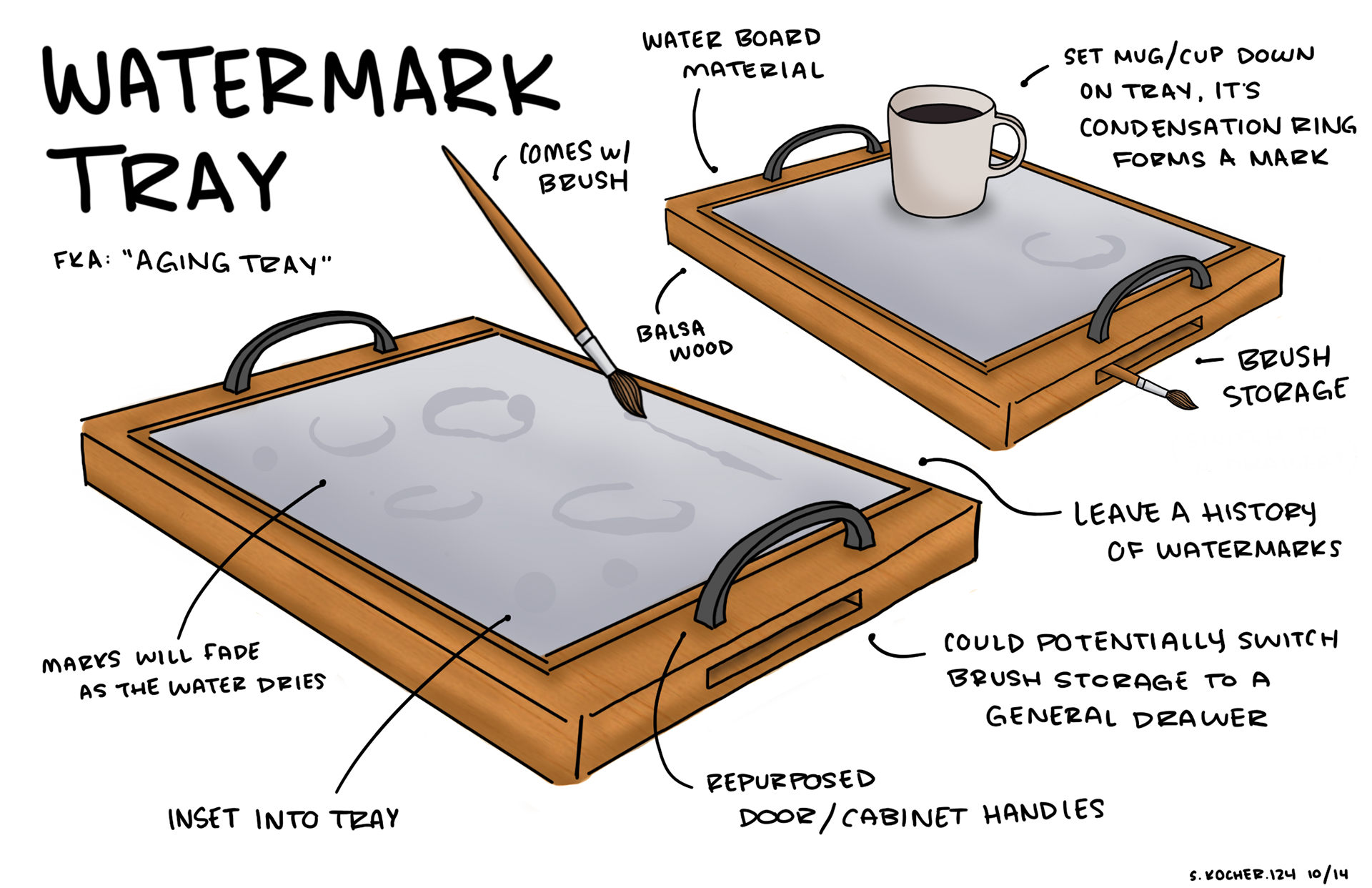

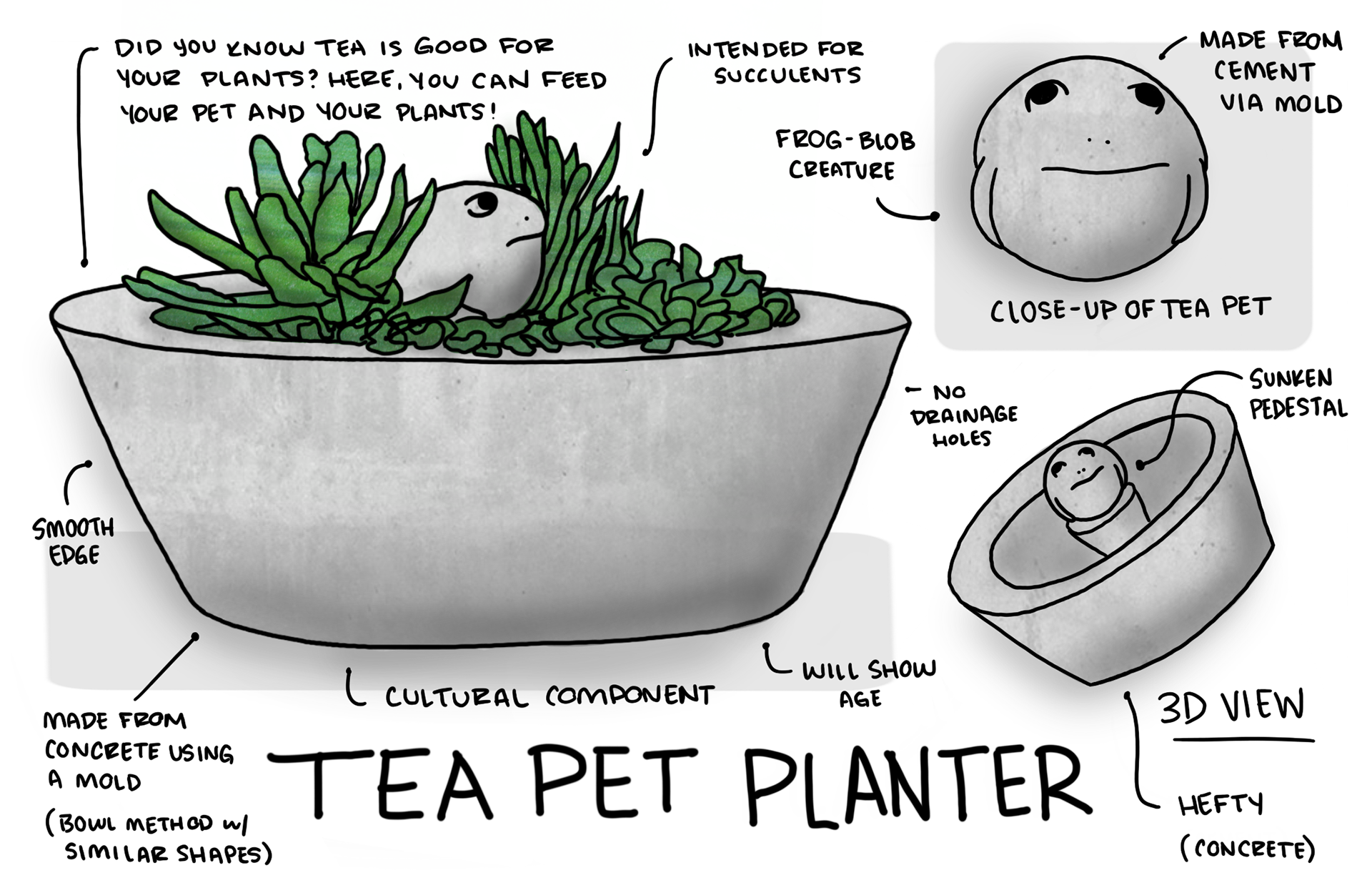

We narrowed our ideas down and I sketched them in slightly higher fidelity.

Here are a few of our favorites:

After much deliberation, we took our ideas through another round of development.

And eventually narrowed it down to our final two:

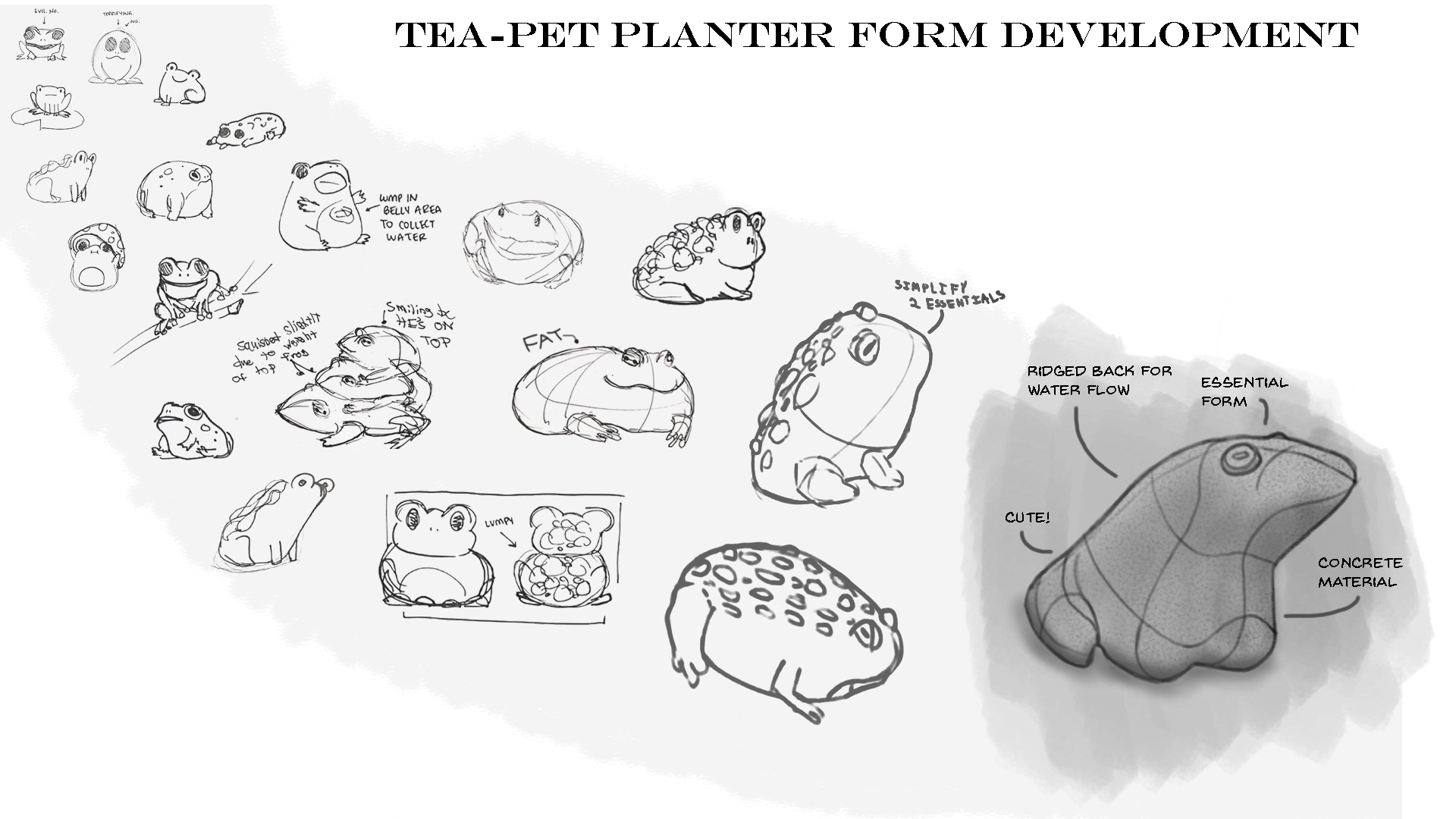

Both concepts went through one more round of development before we jumped into proof of concept. The tea pet planter became much less lumpy, and the tea pet stirrer was given several different faces. Jason sketched out the development of both ideas:

Development of the planter pet shape

Development of the tea pet stirrer face

To prepare for our concept presentation, we began experimenting with materials.

We attempted to mold the tea pet planter from concrete, but ran into a few obstacles when we were unable to separate the concrete from the mold, despite using lubricant:

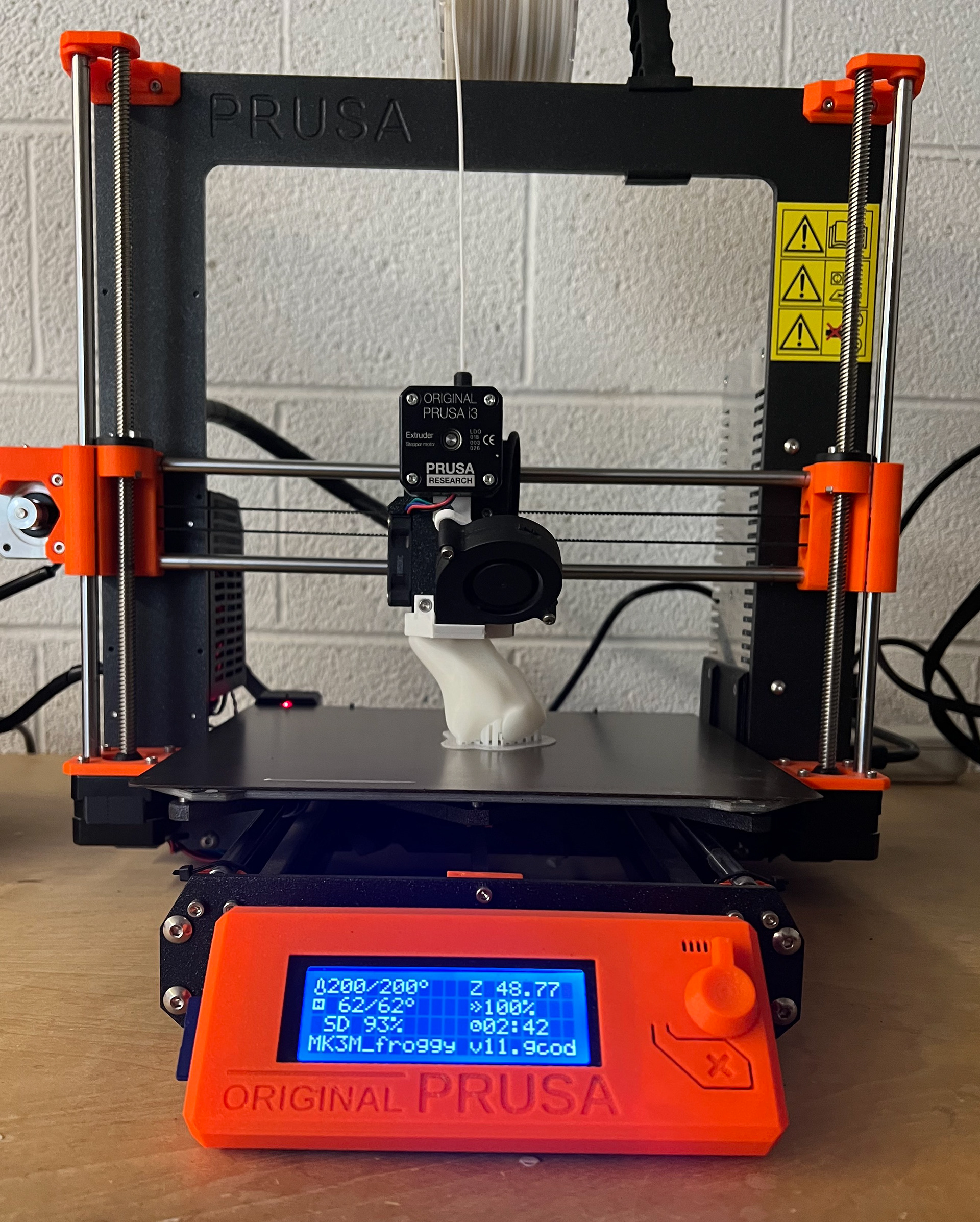

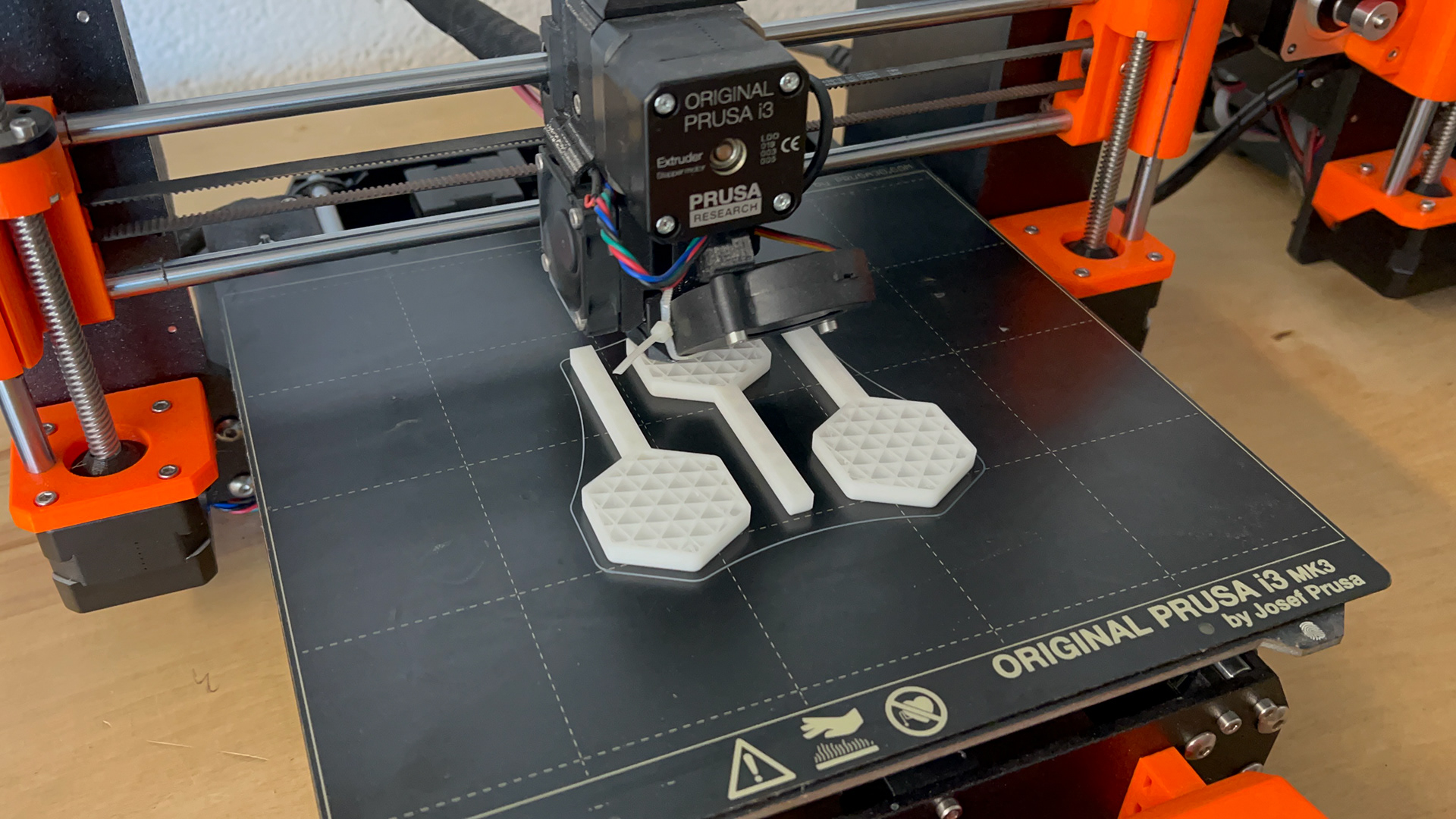

We revised the concept to focus in on just the planter pet itself, marketing it as a tea drinking companion that also encourages one to water their plants. Jason 3D modeled and printed a scale model and experimented with making silicon molds:

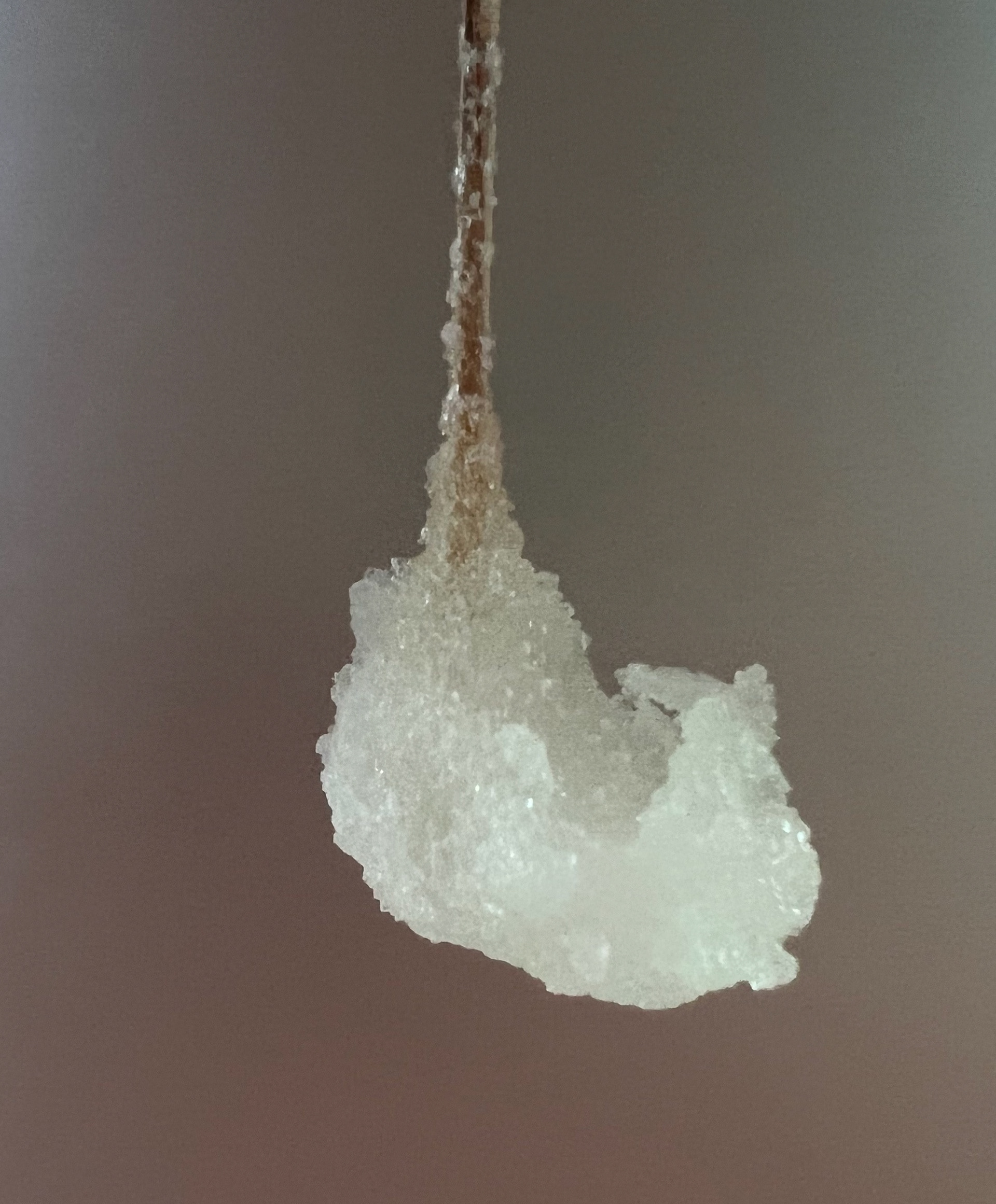

For the stirrers, I took a closer look into laser-cutting pressed palm leaf plates, paint stirrers, and bamboo. I also experimented with making rock candy and honey lollipops for the base of the stirrer.

For our concept presentation, we demonstrated our ability to produce both concepts. The panel chose the tea pet stirrers for us to pursue. See our presentation below:

Making:

To bring our Lollihops into reality, we obtained several reclaimed bamboo cutting boards and cut them into planks, sanding any finish off to laser cut.

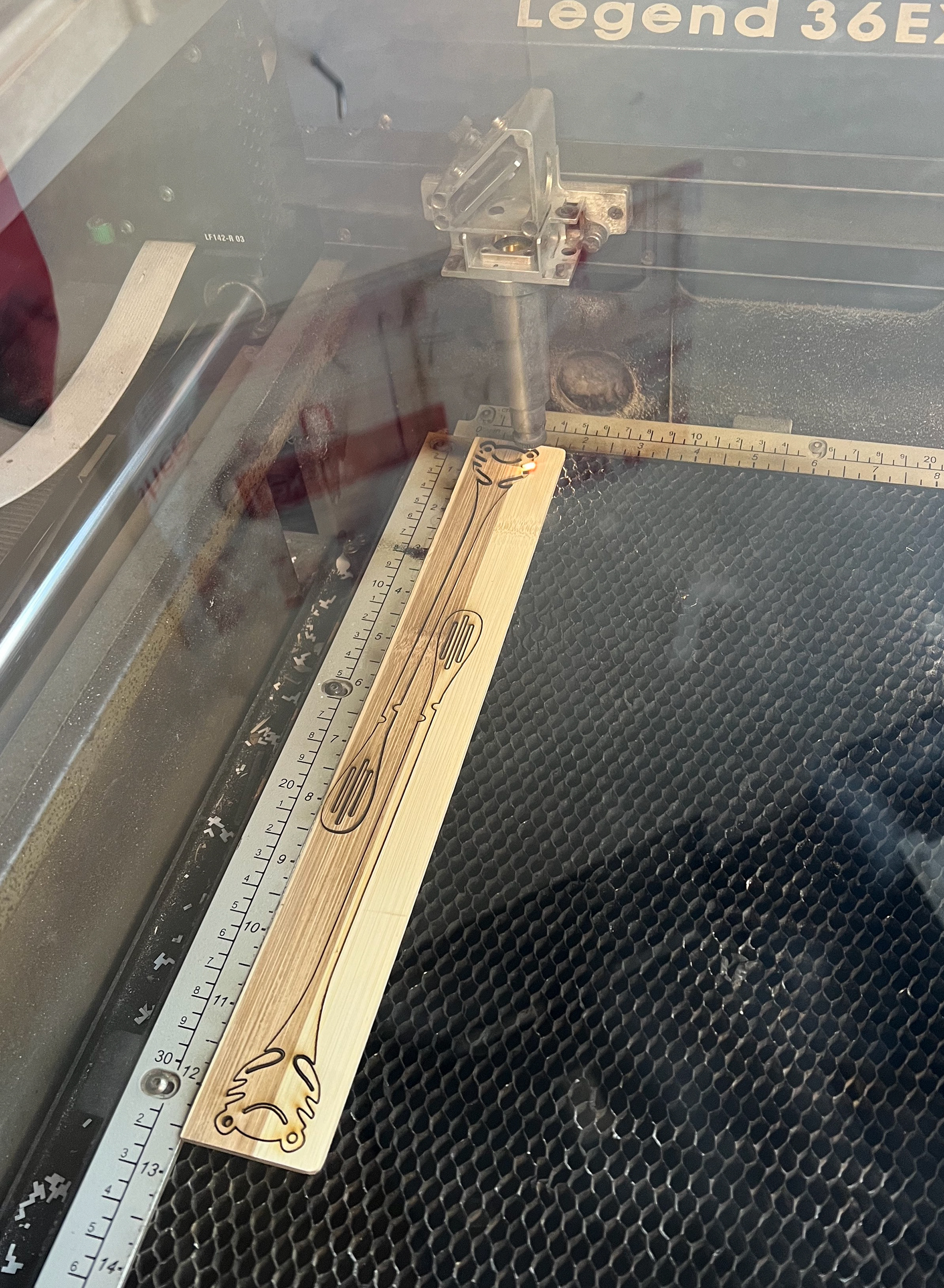

I laser-cut our Lollihops from the bamboo planks, taping the pieces to avoid charring.

Each stick was washed, stained using black tea, and sealed with a food safe wood finish. We designed three different faces stirring ends to create variety. The goal was to sell our Lollihops in packs of 3 for consumers to have one of each.

Each sticks comes with either a honey or chocolate lollipop on their base. This way, the pop melts in consumers' drinks as they stir. On the product packaging, we include both recipes so consumers can remake the ends on the sticks if they so desire.

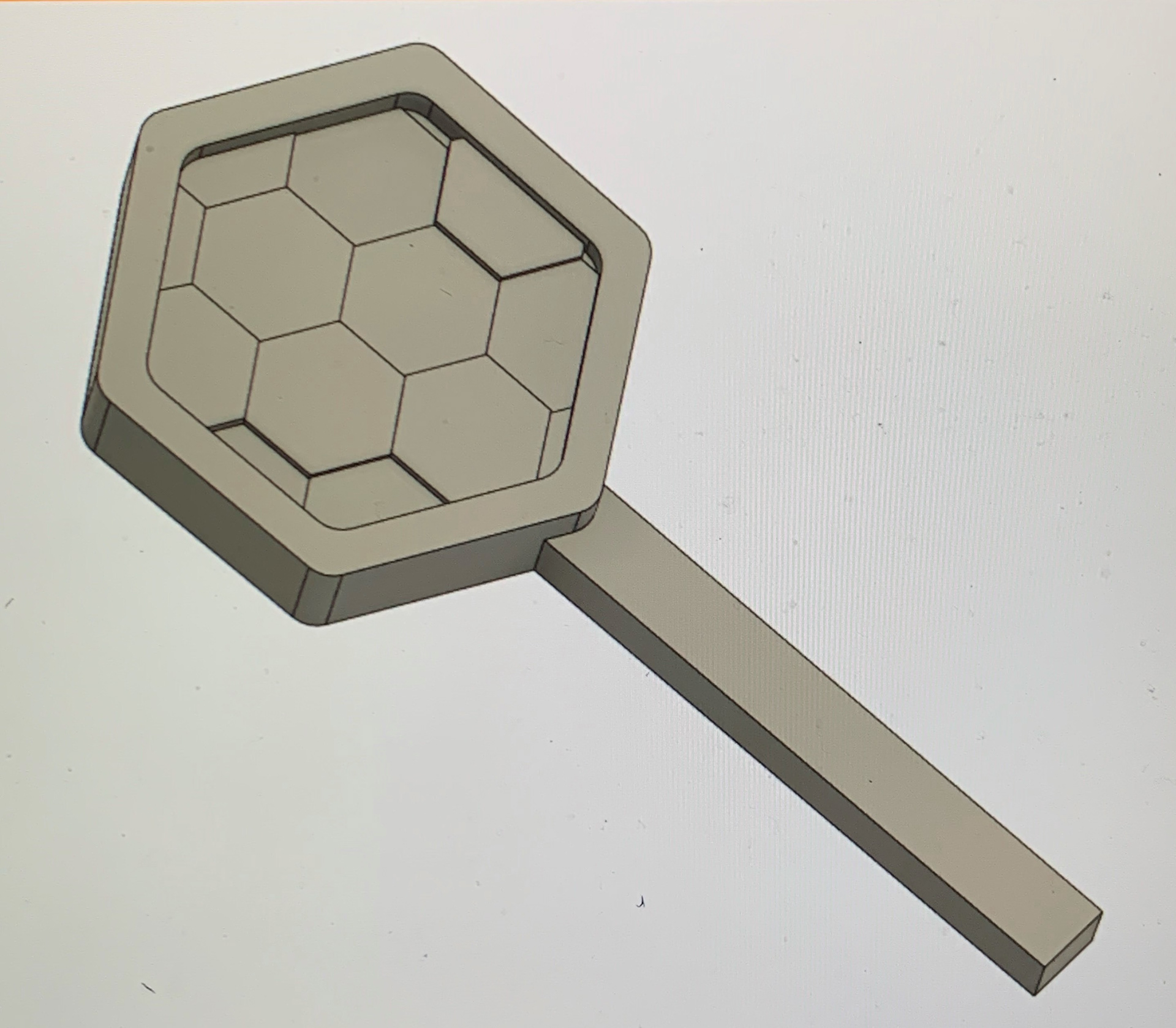

We designed the lollipop base of our stirrers in a honeycomb pattern, as the initial plan for these stirrers was for them to all have honey pops (the chocolate pops were added in later to reach a broader audience). Jason 3D modeled and printed our vision for the base and used those prints to make several molds out of food-safe silicon.

Looking to heighten the quality of our honey pops, we experimented with both a vacuum and pressure pot to reduce the amount of bubbles trapped in the honey. We found the most success with the vacuum pot, but the time required for it to be in the pot nearly matched the time it took for the honey to harden. We were only able to salvage a few honey pops from both experiments.

To make the chocolate pops, I melted chocolate, poured it into Jason's molds, and covered the backs with either sea salt or crushed candy canes for an added touch.

I packaged the pops using compostable cellophane-ish bags, finishing each pack or single stick with a laser-cut tag featuring our logo as well as a QR code leading to a website designed by Jason, featuring both recipes, a look into our making process, use and care instructions, and our promo video. See here: https://lollihops.myportfolio.com

With that, our Lollihops were ready for sale! Enjoy a few of our promo pics here:

And our promo video, edited by me in Premiere Pro:

Here's Jason and I with our booth at Winter Market! We sold all 60 Lollihops in 20 minutes.

Summary:

This project offered a great look into the product development process on both ends, from research to actual craftsmanship. The fact that it was a partner project, too, gave us a better understanding of how to work in a team and collaborate to create something we were both proud of.

This semester, we took a research insight, turned it into a concept, then developed it into a product that we were able to physically sell. We learned about new materials and processes, as well as how to push ourselves and what we thought were our limits past what we believed possible.

"It's always tea time!"

- The Mad Hatter, Alice in Wonderland